Cost Of Vertical Roller Mill

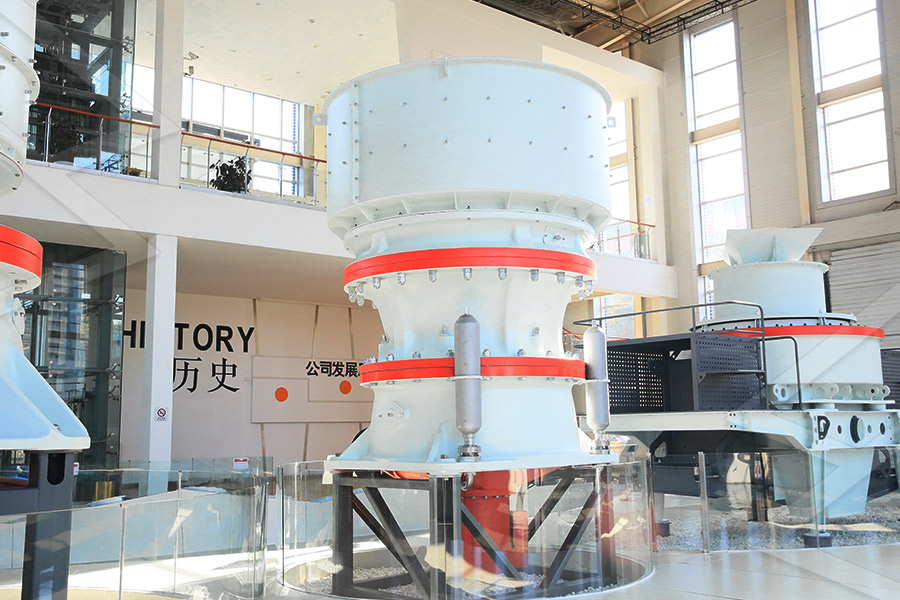

Vertical roller mill for raw Application p rocess materials

2016年1月4日 Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the Review on vertical roller mill in cement industry its China Vertical Roller Mill wholesale Select 2024 high quality Vertical Roller Mill products in best price from certified Chinese Powder Grinding Machine manufacturers, Grinding Mill suppliers, China Vertical Roller Mill, Vertical Roller Mill Wholesale Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It Vertical roller mills FLSmidth Cement

.jpg)

Installed cost comparison for cement grinding systems

2004年4月30日 As the Vertical Roller Mill (VRM) becomes more widely accepted for new cement grinding systems differences in installed costs between a VRM and a ball mill systOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It OK™ Raw and Cement Mill FLSmidth Cement2023年11月16日 HRM vertical mill series vertical mill is highefficiency, energysaving and hitech equipment with function of drying and grinding, which is developed by absorbing advanced foreign technology on the basis of more Vertical Roller Mill Vertical Roller Mill and 2024年10月15日 Vertical roller mill for cement (LGMC5725, 225t/h), annual output 1,600,000 ton We have four production lines that have the capacity to produce large steel castings, large highvalue forgings, large annular parts Vertical Roller Mills Cement Processing

.jpg)

Analysis of vertical roller mill performance with changes in

2022年5月31日 According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higher It may also account for 18% of the global One of the main challenges is the high initial cost of the equipment VRMs are more expensive than traditional grinding mills, and the cost of installation can be significant Another challenge is the maintenance and repair of the equipment, Application of Vertical Roller Mill in Cement 2018年7月19日 Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsRAYMOND® ROLLER MILLS ThomasnetThe spotlight has also turned on operating and maintenance costs (OPEX) The energy consumption of a mill, as well as of the entire grinding system or section, plays a significant role in decisions made by plant operators Vertical roller quadropol® thyssenkrupp Polysius Grinding

Application of Vertical Roller Mill in Cement

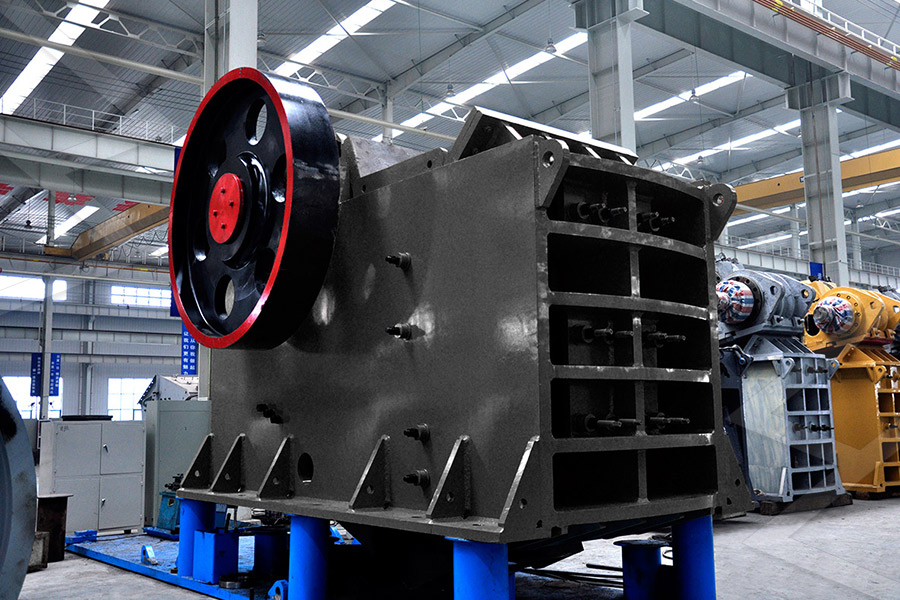

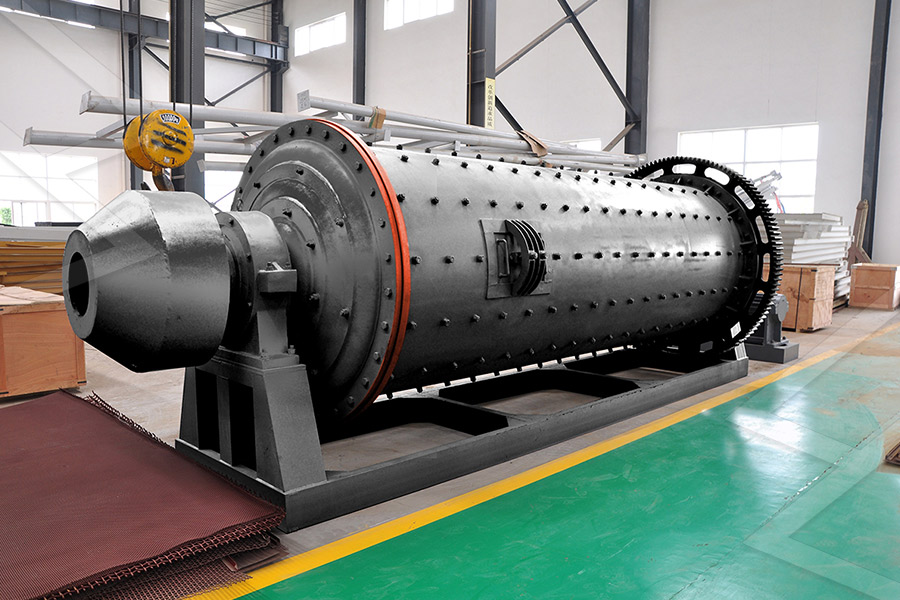

Learn how vertical roller mill technology is transforming the cement industry Explore its benefits, efficiency, and ecofriendly features Discover why it is the goto solution for sustainable cement production VRMs are more Disadvantages of Vertical Roller Mills: High Initial Cost: VRMs have a higher capital cost compared to ball mills The advanced technology and components used in VRMs contribute to this increased investment, which may be a barrier for Vertical roller mill vs ball mill for cement grinding: 2023年1月10日 Advantages of Slag Vertical Roller Mill 1 Costeffective, less comprehensive investment Large functions are integrated in one, occupying an area of about 50% of the ball mill system, and can be arranged in the open air, greatly reducing investment costs; the system design is simple and reasonable, saving the total investment in equipment Slag Vertical Roller Mill msbmchina2016年1月23日 The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the Cement grinding Vertical roller mills versus ball mills

.jpg)

VRM – AMCL Machinery Limited

UBE Vertical Roller Mill performs drying, grinding, classification and pneumatic transportation simultaneously which helps to refine mill structure and lowers mill weight eventually reduced the cost Four Roller Arrangement Six Roller Arrangement Vertical Mills are more preferred over ball mill so as to take an advantage of lower 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools2024年10月15日 Our team of experts will help global customers develop a reliable, energysaving and highefficiency vertical roller mill grinding solution by taking advantage of our technological development strength, core manufacturing expertise, strict quality control measures and excellent customer service Low operaion costVertical Roller Mills Cement Processing Equipment CITIC HIC

.jpg)

Vertical Roller Mill Manufacturers, Suppliers, Dealers Prices

Find Vertical Roller Mill manufacturers, suppliers, dealers latest prices from top companies in India Buy from a wide range of Vertical Roller Mill online ZT1000 Vertical Roller Grinding Mill Machine Price Trend : 1000000 00 USD ($) Hgm148 Ultrafine Powder Vertical Roller Mill NonMetallic Minerals Get Best Deal2021年1月1日 Increase productivity of vertical roller mill using seven QC tools Praveen Pareek 1 and Dr Vijayendra Singh Sankhla 1 lowering breakdowns and optimizing the grinding process which eats almost 60% of power cost In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power Increase productivity of vertical roller mill using seven QC tools2023年11月16日 Company Introduction: CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and Vertical Roller Mill Vertical Roller Mill and Slag Vertical Roller MillSBM Industrial Technology Group

.jpg)

OK™ Raw and Cement Mill FLSmidth Cement

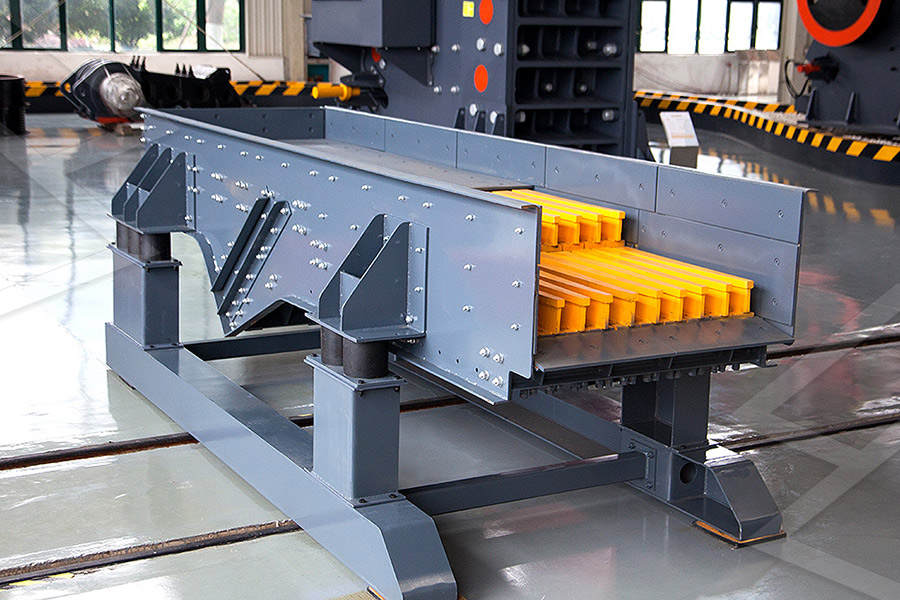

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetime2024年10月16日 Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical mill Get Price Model Main Motor(kW) Less than 2μm=30% output (t/h) Less than 2μm=45% output (t/h) Less than 2μm=60% output (t/h vertical roller mill, vertical coal mill, vertical slag mill, 2017年8月11日 the size of the rollers of a Loesche mill with four or three rollers made it possible to use the existing roller modules from mills that have already been operating successfully for many years The roller module ( Fig 3) of a Loesche mill consists of the grinding roller, the spring system, which transmits its hydrauRedundancy and interchangeability – large vertical roller 2017年2月23日 Vertical Roller Mill Drives Peter Boiger RENK AG 86199 Augsburg, Germany peterboiger@renk Abstract The Vertical Roller Mill (VRM) has proven a universal tool for grinding limestone, clinker and slag in the cement industry The maximum mill powers doubled from 2500 kW in the midseventies to 5000 kW in the nineties Today, another 20 yearsDevelopment of the 4th Generation Vertical Roller Mill

Vertical mill Vertimill® 7000 Metso Corporation roller /

roller Orientation vertical Product applications mineral wool, for metals, for limestone, for coal grinding Other characteristics In fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than for 2022年5月18日 Coal grinding on MPS vertical roller mills – Pfeiffer quality you are used to //When it comes to the grinding of coal or petcoke, don’t make any concessions Rely upon Pfeiffer’s renowned quality Our MPS vertical roller mills are perfectly suited for the grinding of fossil fuels, combining high availability, lowest wear rates,PFEIFFER MILLS FOR THE CEMENT INDUSTRY2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this mill LM series LM Vertical Roller Mill, Vertical Mill

A New Gearbox Generation for Vertical Roller Mills

11 Function of the main gearbox in a vertical roller mill The main gearbox of a vertical roller mill has to perform two major tasks (see also Fig 2): 1 Transmission of the power from the main motor to the grinding table 2 Absorption of the grinding forces and the table weight 1424403723/06/$2000 (c)2006 IEEE2023年9月21日 Common types of grinding mills include ball mill, Raymond mill, vertical roller mill and ultrafine mill, each with unique advantages for specific applications Sand Making Machine The sand making machine, also known as Vertical Shaft Impactors, is a specialized equipment used for producing artificial sand from rocksA Comparative Analysis: Vertical Roller Mill vs Ball Mill2021年1月1日 The wear rate in g/t is higher in the ball mill than in the vertical mill or highpressure roller, but as the unit cost for wear parts is lower for the ball mill than for the vertical or highpressure mill, the total cost of wear parts is similar for the three mill systems [113,115–117] Investment costReview on vertical roller mill in cement industry its The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

How does vertical roller mill work? ball mills supplier

Lower operating costs: Vertical roller mills have lower operating costs than traditional mills due to their lower power consumption, maintenance costs, and overall footprint Higher grinding capacity: Vertical roller mills can handle up to 25% more capacity than traditional mills, making them ideal for large cement plants with high throughput The lower rocker arm is an important part of the vertical roller mill and its lightweight design is of great significance for reducing the mass and production cost of the roller millTechnical specifications of vertical roller coal mill2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical Roller 2024年10月13日 Advantages of Vertical Roller Mills in Cement Production: 1 Energy Efficiency: VRMs are known for their high energy efficiency They consume up to 40% less power than traditional ball mills, making them a costeffective choice for cement plants 2 Space Savings: The compact design of VRMs means they require less space than ball millsThe role of vertical roller mills in the cement industry NEWS

RAYMOND® ROLLER MILLS Thomasnet

2018年7月19日 Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsThe spotlight has also turned on operating and maintenance costs (OPEX) The energy consumption of a mill, as well as of the entire grinding system or section, plays a significant role in decisions made by plant operators Vertical roller quadropol® thyssenkrupp Polysius Grinding Learn how vertical roller mill technology is transforming the cement industry Explore its benefits, efficiency, and ecofriendly features Discover why it is the goto solution for sustainable cement production VRMs are more Application of Vertical Roller Mill in Cement Disadvantages of Vertical Roller Mills: High Initial Cost: VRMs have a higher capital cost compared to ball mills The advanced technology and components used in VRMs contribute to this increased investment, which may be a barrier for Vertical roller mill vs ball mill for cement grinding:

Slag Vertical Roller Mill msbmchina

2023年1月10日 Advantages of Slag Vertical Roller Mill 1 Costeffective, less comprehensive investment Large functions are integrated in one, occupying an area of about 50% of the ball mill system, and can be arranged in the open air, greatly reducing investment costs; the system design is simple and reasonable, saving the total investment in equipment 2016年1月23日 The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the Cement grinding Vertical roller mills versus ball millsUBE Vertical Roller Mill performs drying, grinding, classification and pneumatic transportation simultaneously which helps to refine mill structure and lowers mill weight eventually reduced the cost Four Roller Arrangement Six Roller Arrangement Vertical Mills are more preferred over ball mill so as to take an advantage of lower VRM – AMCL Machinery Limited2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in

.jpg)

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around 2024年10月15日 Our team of experts will help global customers develop a reliable, energysaving and highefficiency vertical roller mill grinding solution by taking advantage of our technological development strength, core manufacturing expertise, strict quality control measures and excellent customer service Low operaion costVertical Roller Mills Cement Processing Equipment CITIC HIC